Measuring Contact Wires

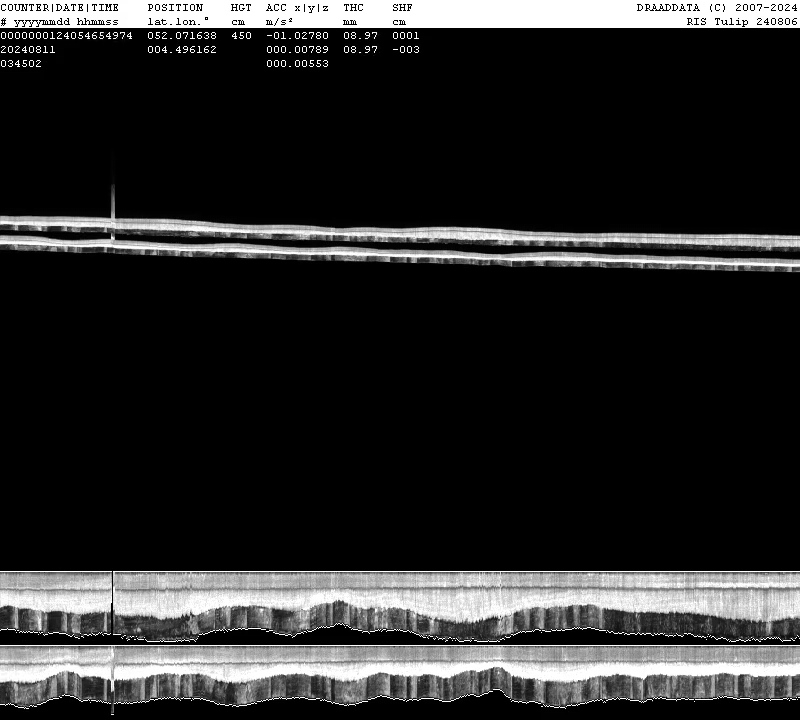

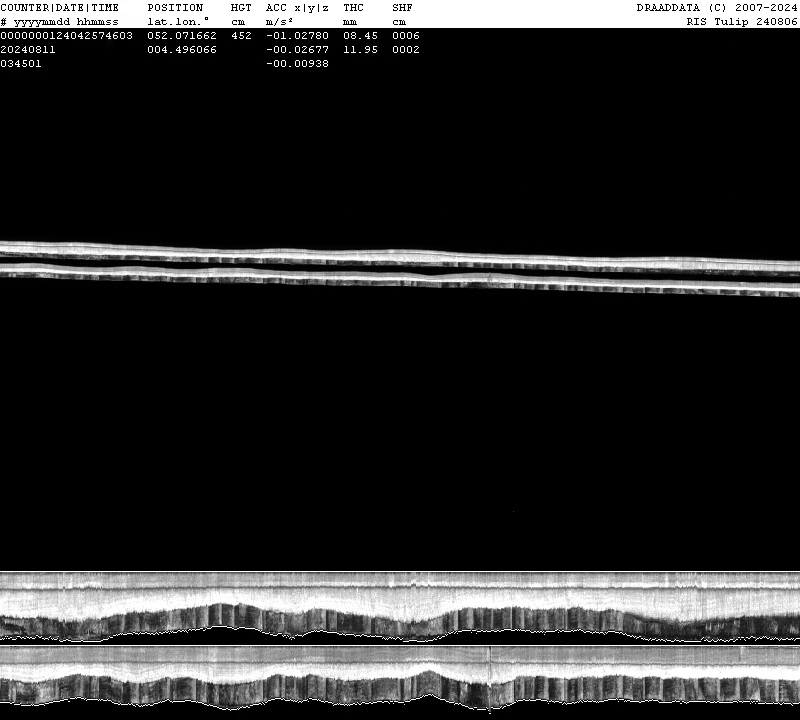

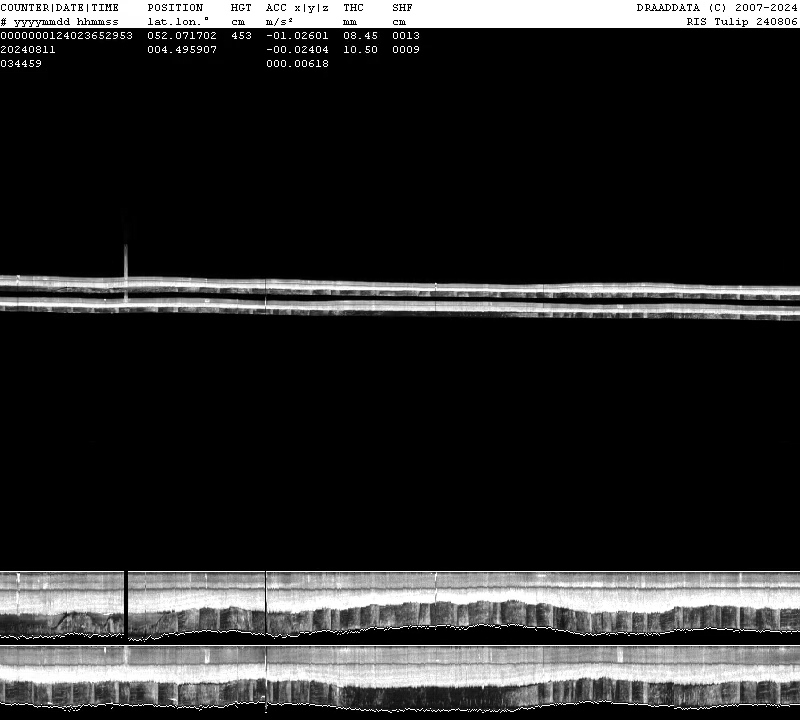

Measurements are fully automated and are facilitated by rail vehicles suitable for both train and tram tracks. The wire thickness is measured using a compact and state-of-the-art contact wire inspection system (RIS). This advanced system measures the wire thickness directly and with the highest possible accuracy. The measurements are carried out both during the day and at night.

Analysing Data

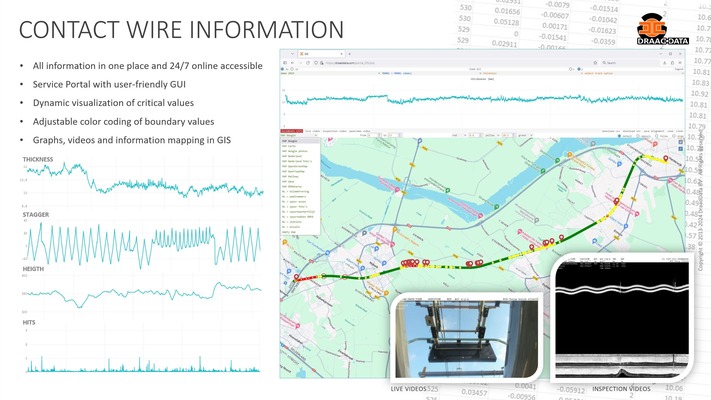

Data are automatically analysed. The results are available within 24 hours after a measurement. Thin spots, including those under clamps, are detected by an artificial neural network and through video inspection. The results are accurate, free of false positives and positioned on the centerline of the track. Information about wire thickness, stagger, height, and dynamics is made available online.

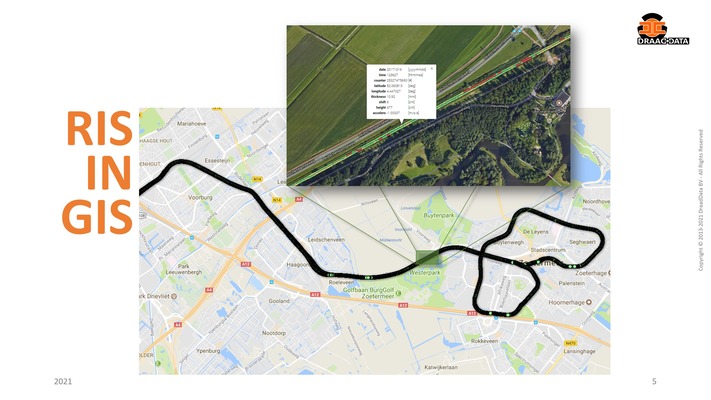

Visualizing Information

Visualizing wire information is effortless using the Service Portal, which provides free access to a range of useful tools for viewing and further analyzing the measurement results. The platform features an interactive GIS environment complete with various geographic maps and other rail-related information. In addition, users can easily track the maintenance status of incidents.